imagens

Products menu

Kaolin

ALUMINO SILICATO DE POTÁSSIO (CHINA CLAY)

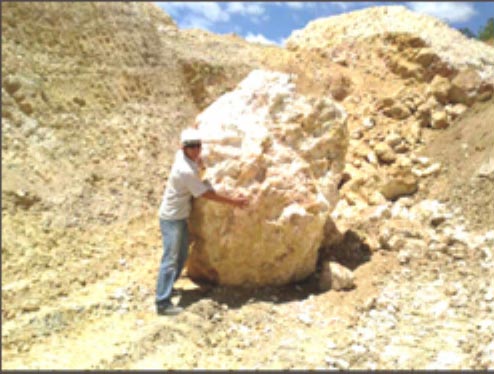

IN NATURA

imagens

Kaolin - White Pearl

Kaolin - Yellow Gold

imagens

Benefited

imagens

Chemical analysis

| METHOD | WIGHT | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 | XRF01 |

| ANALYTE | Wgt | AI2O3 | CaO | Fe2O3 | K2O | MgO | MnO | Ma2O | P2O5 | SiO2 | TiO2 | LOI | Fe | SUM |

| UNIT | Kg | % | % | % | % | % | % | % | % | % | % | % | % | % |

| MDL | 0.01 | 0.1 | 0.01 | 0.01 | 0.01 | 0.1 | 0.01 | 0.1 | 0.01 | 0.1 | 0.01 | -5.11 | 0.007 | 0.01 |

| Pearl White(Other) | 1.12 | 16.69 | 0.014 | 1.482 | 2.683 | 0.71 | <0.01 | <0.1 | 0.017 | 72.60 | 1.036 | 4.72 | 1.036 | 100.03 |

| Golden yellow (Other) | 1.50 | 17.10 | 0.016 | 7.156 | 2.713 | 0.78 | 0.019 | <0.01 | 0.050 | 65.69 | 0.992 | 5.46 | 5.004 | 100.09 |

| LS:Above the upper limit of the curve. | ||||||||||||||

O KAOLIN extracted by MinaSilicio presents fine granulometry with material 100% within the standards required by the industries that consume mineral loads. It improves the properties of the final products like: Viscosity, gloss, appearance, dispersion time and coverage.

Kaolin is a mineral good that has a wide use in the industry due to its technological characteristics:

- Chemically inert;

- Non-toxic and safe for ingestion and handling;

- Coverage capacity when used as pigment;

- Application as a mineral charge;

- Reduced costs.

Typical physical properties:

- Estabilidade física;

- Physical stability;

- Soft and non-abrasive;

- Homogeneous granulometric distribution: fine powder;

- Colors: White Pearl (lightness) / Yellow Gold;

- Apparent density: 1,8 g / cm³;

- Oil Absorption: 42%;

- It presents low thermal and electrical conductivity;

- Granulometry: <75 μm.

imagens

The works carried out to obtain KAOLIN by MinaSilicio, are carried out within the technical norms and under strict quality control, from the extraction to the final processing. Our biggest challenge is to harmonize the SOCIAL part with the ENVIRONMENT. Our Mining Engineers, Geologists and Technicians are always aware of any damage that may be caused to their extraction, and immediately adopt solutions to the rebalance of the area eventually affected, preserving to the maximum the original fauna and flora. Our infrastructure allows us to have an exemplary quality in the products that are offered to the market and highly competitive prices. We perform SERIOUS work and look for companies that are also committed to the same goals to form a lasting partnership.

imagens

imagens

The KAOLIN extracted by MinaSilicio is special in its composition, since it has all the basic and essential requirements for several applications in various segments of Agriculture, Poultry, Fish farming, PET and processing industries due to their color, granulometry, form of mineral components , refractive index, oil absorption, chemical and intrinsic composition of the deposit that form the set of characteristics that give the ore quality to be classified as exceptional load for use in:

Animal food:

Kaolin is used as a vehicle to give volume and facilitate homogenization. It aggregates and preserves the nutrients as it does not cause changes in the product. Kaolin is an inert material, so it is neither toxic nor perishable. Promotes weight gain, increases feed efficiency and helps strengthen the immune system of animals.

See more photos

Ink:

Used as cargo due to its granulometry and whiteness, it reduces costs by replacing more expensive pigments and provides excellent coverage to wet and dry with increased washability. It acts as extender of titanium dioxide (TiO2). It also exhibits excellent chemical inertia, film formation, matting of the final product, surface adhesion, weatherability (UV protection) and refined and soft finishing to the touch of the final product.

Paper:

Kaolin is widely used in the paper industry which consumes about 45% of world production. In it, it is used as filler, (load) and can be used for addition or replacement of plastic clays and calcium carbonate among others. It contributes to the brightness, uniformity, smoothness and print quality. Help also in the environment, because it avoids the extraction of trees.

Eraser:

Improves the performance of Rubbers. Used as a mineral load with low coefficient of friction, in addition to reducing the costs, they confer several advantages to the final product, such as: It increases the elongation of rupture, it helps in the calandragem providing a more uniform lamination, it avoids the formation of bubbles, it assists in the pressing and vulcanization.

Plastic:

Kaulins are an integral part of technological advances in plastics. Within this area, Kaolin offers many benefits for thermoplastic and thermoplastic polymer applications. Kaulins are used to enhance visual appeal, strength, flexibility, electrical properties, durability and cost.

Adhesives and Sealants:

It is used in adhesives and sealants due to the geological properties that incorporate the formulations. Its physical and morphological characteristics influence the absorption of resins or oil, consistency of the adhesive or sealant, stability, porosity, flexibility, stiffness, density, rheology, dry and wet strength.

Porcelain / Sanitary Ware:

In the production of porcelain and sanitary ware, Caulins are increasingly consumed due to their damp plasticity and their property as flux or vitrifying. Because it has a fine grain size of its mineral constituents and having these lamellar forms the ore contributes to the homogeneity of the floor and also to give coloration after the firing.

Cosmetics and soaps:

Chemically inert, it is used as a filler and carrier for a wide variety of products that are made for direct contact with human skin such as: Masks, toothpastes, soaps, creams anti-inflammatory, ointments and makeup among others.

imagens

Other applications

KAOLIN is also used in the manufacture of detergents, filler for plaster, linoleum and oiled coating, as an inert carrier for insecticides, mild abrasives and hardener in the textile industry, among others.

MinaSilicio GMA Mineradora LTDA tem uma equipe especializada para enviar amostras de nosso CAULIM para análise em laboratório de sua confiança, a fim de que possa provar e confirmar a qualidade do nosso minério.

Download do Arquivo (PDF)

MinaSilicio GMA tiene un equipo especializado para enviar muestras de nuestro CAOLÍN para analizar en laboratorio su confianza para que pueda probar y confirmar la calidad de nuestro mineral

Descargar el archivo (PDF)

MinaSilicio GMA has a specialized team to send samples of our KAOLIN for laboratory analysis of his trust, so that it can prove and confirm the quality of our ore.

File Download (PDF)

MinaSilicio GMA Mineradora LTDA tem uma equipe especializada para enviar amostras de nosso QUARTZO para análise em qualquer laboratório de sua confiança, a fim de que possa provar e confirmar a qualidade do nosso minério.

- Entre 99,25% - 99,75% de sílica pura (SiO²)

- Entre 0,39% - 0,42% Ferro (Fe₂O₃)

Download do Arquivo (PDF)

MinaSilicio GMA tiene un equipo especializado para enviar muestras de nuestro CUARZO para su análisis en cualquier laboratorio de su confianza, a fin de que pueda probar y confirmar la calidad de nuestro mineral.

- Entre 99,25% - 99,75% de sílice pura (SiO²)

- Entre 0,39% - 0,42% hierro (Fe₂O₃)

Download do Arquivo (PDF)

MINASILICIO GMA MINERADORA LTDA HAS A SPECIALIZED TEAM TO SEND SAMPLES OF OUR QUARTZ FOR ANALYSIS IN ANY LABORATORY OF ITS CONFIDENCE, AN END OF WHICH IT CAN PROVIDE AND CONFIRM A QUALITY OF OUR ORE.

- In between 99,25% - 99,75% of pure silica (SiO²)

- In between 0,39% - 0,42% Iron (Fe₂O₃)

File Download (PDF)

Ela Também trabalha incansavelmente para implantar a ISO 9001 e a ISO 14001. com todo este cuidado e atenção, podemos garantir que ela produz produtos de baixíssimo impacto ambiental e com Excepcional qualidade, e tem como principal objetivo e meta, a conquista e a satisfação dos nosso clientes e funcionários.

También trabaja incansablemente para implantar la ISO 9001 y la ISO 14001. Con todo este cuidado y atención, podemos garantizar que ella produce productos de bajísimo impacto ambiental y con Excepcional calidad, y tiene como principal objetivo y meta, la conquista y la satisfacción de los clientes nuestros clientes y empleados.

She also works tirelessly to implement ISO 9001 and ISO 14001. With all this care and attention, we can guarantee that she produces products of very low environmental impact and with exceptional quality, and has as main objective and goal, the achievement and satisfaction of our customers and employees.