imagens

text

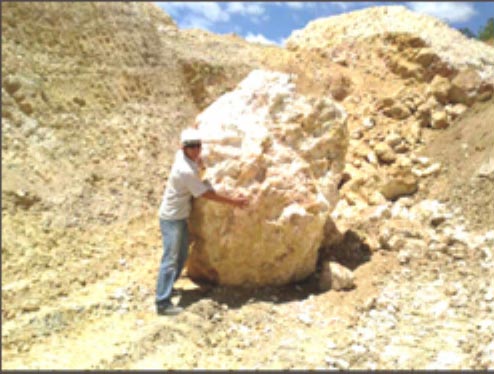

Product obtained from ROCKS crushing of QUARTZ proved in laboratory tests to have a better resistance to durability in grating theSANDS extracted from RIVERS. Due to the fact that it does not have contaminating elements such as organic residues and mainly faecal coliforms present in most SANDS available in the market, it provides a better homogenization in the preparation and is ideal for the composition of concretes, mortars, against floors, blocks and precast between others, thus providing a better finish and durability for the project. Most importantly, because it originates and crushes QUARTZ ROCKS, they do not reconfigure the originality of Rios and Várzeas, thus conserving the fountains and preserving nature, that is, a 100% ECOLOGICAL product.

text

Quartz sand is a natural, cohesive and non-plastic substance from the disintegration of QUARTZ ROCKS, with a particle size ranging from 60 to 2000 μm and high in silica (SiO2>90%). The higher the SiO2 content in the sand composition, the higher its purity, and therefore the higher its value added. In addition, it is one of the materials that has greater diversification in its use, due to the common occurrence and its properties like hardness, chemical stability and resistance to high temperatures. Sands can be used in the manufacture of various types of products in the ceramic industry such as tiles, bricks, glass, coatings, electrical insulators, crockery, sanitary ware, cement and refractories, as well as in the metal industry and sand molds.

Thin sand

It has a maximum dimension of 0.25 mm. In civil construction it is the most suitable for plastering in general, used in construction and renovation, in the manufacture of concrete and mortars, and for composing the coarse or medium sands to improve the distribution of size among the grains. Its use is highly regarded in finishes and internal and external coatings.

Average sand

It is widely used because its components allow it to be used practically in all phases of the work. With sizes between 0.25 mm and 1 mm, the average sand has a very wide use in the market of works and reforms, because its granulometry characteristic allows the use in practically all the steps of a project, however it is not recommended for finishes. The medium sand can be used for mixing in the mass of cement and is ideal for making the plasters on walls and walls, against floors and laying of masonry.

Gross sand

It has a mesh of 30 mm, is used by a need for a rough concrete, (more resistant) Normally, in larger buildings and we can carry more weight. Used to do that in general, and just like the average sand, it can also be used to make slab on walls and walls. It is ideal for mixing in the mass of cement. It is also more used as an aggregate in civil construction for manufacturing concrete and brick laying on walls that are plastered. The coarse sand confers greater resistance to works and therefore is widely used as a base for counter floors and slabs.

Carrosel